How do you manage your welding data?

Dealing with the volume of welding data can be overwhelming. That’s why it’s crucial to plan, record, document, and analyze welding data accurately.

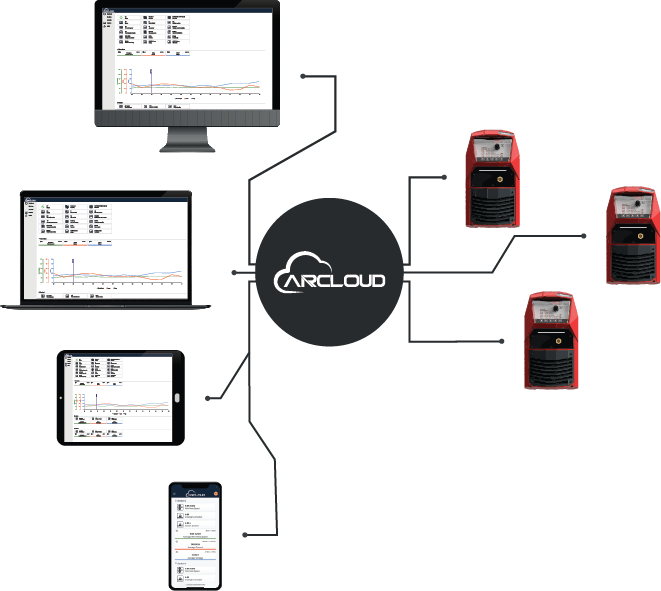

ARCloud aims to provide high-performance production processes for the smart factories of the future with seamless welding technology.

The benefits of ARCloud are very clear.

Improves your quality assurance.

ARCloud ensures that components are managed according to welding instructions, minimizing errors. In some cases, it detects errors and takes steps to eliminate them. It ensures sustainable weld seam quality through documentation of welding parameters and welder qualifications.

Your productivity increases.

Predetermined welding parameters significantly reduce the risk of errors, while ensuring welding quality and longer arc times contribute to high performance in production processes.

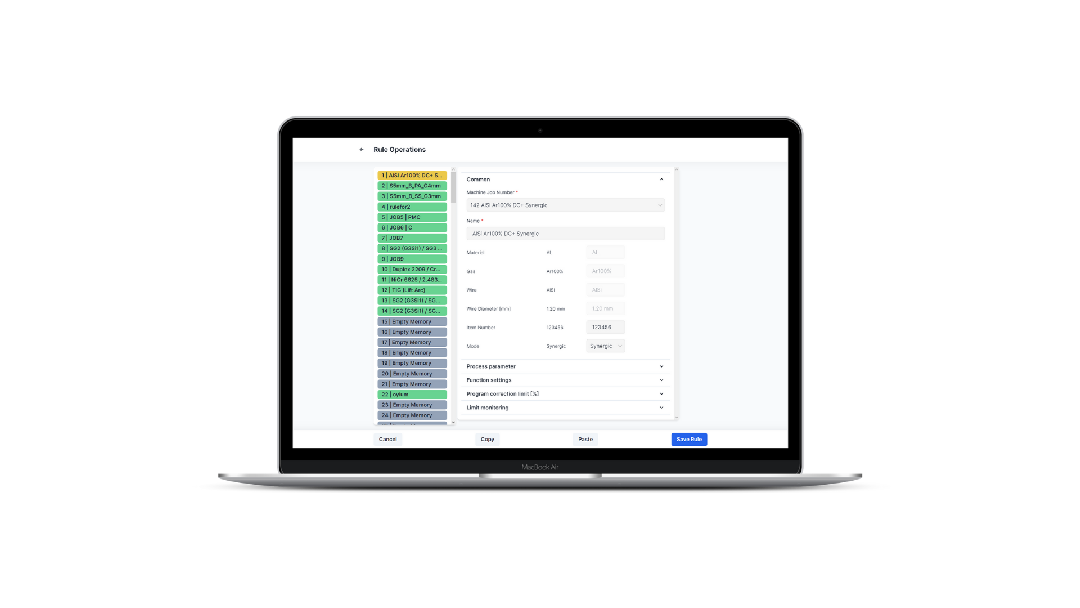

Reduces the costs of consumption value.

Reduces the costs of consumption. Provides the opportunity to record and analyze consumption values such as energy, gas, and consumables such as wire, ultimately saving money by reducing consumption costs.

Network solutions.

Offers the privilege of planned maintenance.

Based on consumption analysis, it plans the maintenance process of the welding machine, facilitating the tracking of maintenance and supporting repair. This ensures that welding machines and components operate at high efficiency.

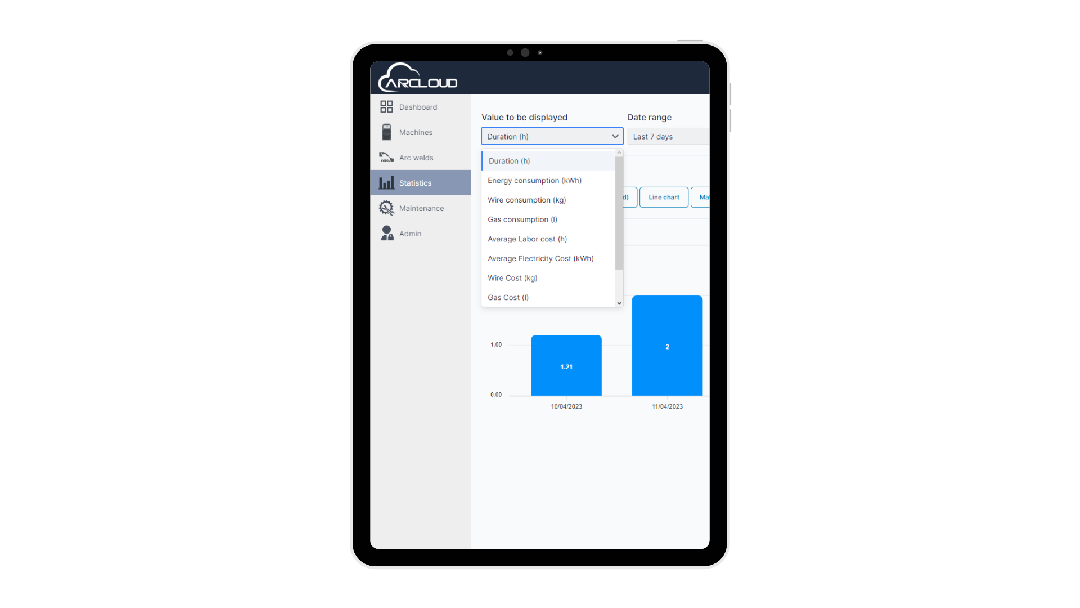

Faster.

Time and Cost Savings

It allows you to track welding information quickly, in detail and instantly, to reduce time and paper waste with automatic full documentation, to detect pauses in the production process and to make the necessary improvements in a short time.

Safe.

Ensures Safety in Production

It allows you to minimize error risks and manage user authorizations in a centralized manner.

Efficient.

Increases Productivity

It enables the detection of optimization potential, uninterrupted weld seam monitoring, and all data on system status at a glance.

Documentation and Analysis

Data interfaces make it possible to transfer all available information to customer documentation and analysis software.

Data Exchange

Capacity and quality data can be exported to higher software systems such as ERP for centralized control over the entire production.

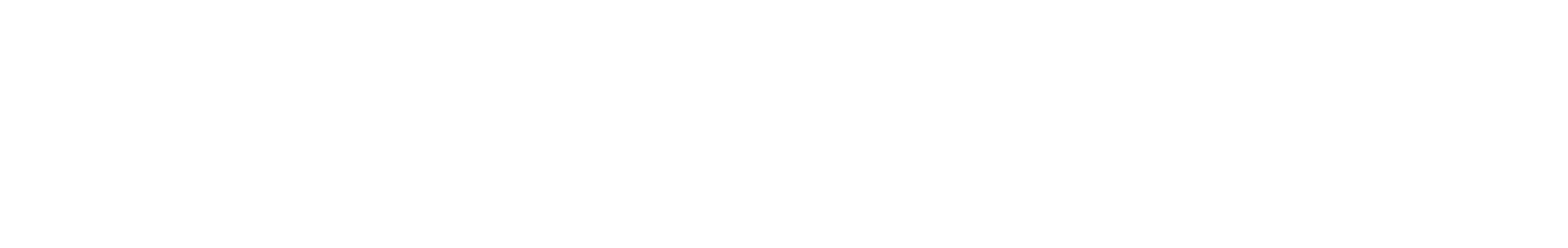

Parameter Input

To avoid incorrect settings, pre-programmed jobs and/or setpoints are selected by a higher control unit in accordance with a welding task.

Special Repair Solutions

Maintenance works may be planned and optimized based on weld data analysis.

Reach Us

LET’S CREATE SOLUTIONS FOR YOU.

Share your opinion and inquiry with us and we’ll get back to you as soon as possible.