KM500

Simple design, easy to useStrong and reliable solution

KM500 Synergic is welder friendly with its simple and intuitive interface. It provides the possibility to apply gas metal arc (MIG/MAG), argon (TIG), and coated electrode (MMA) processes in a single machine. With its durable and functional design, it can be used safely in all kinds of harsh working conditions.

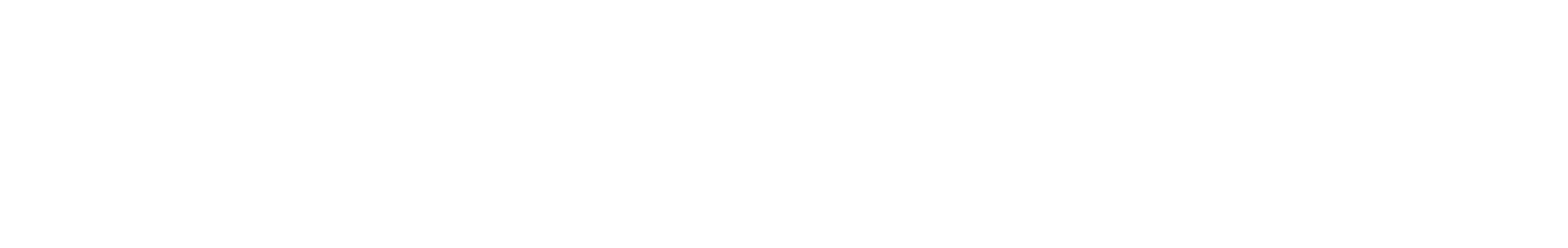

Welder-friendly operation

The KM500 Synergic offers an intuitive interface that highlights the settings users use most frequently. Thanks to its effortless and user-friendly interface, it is designed to reduce the need for trained welders.

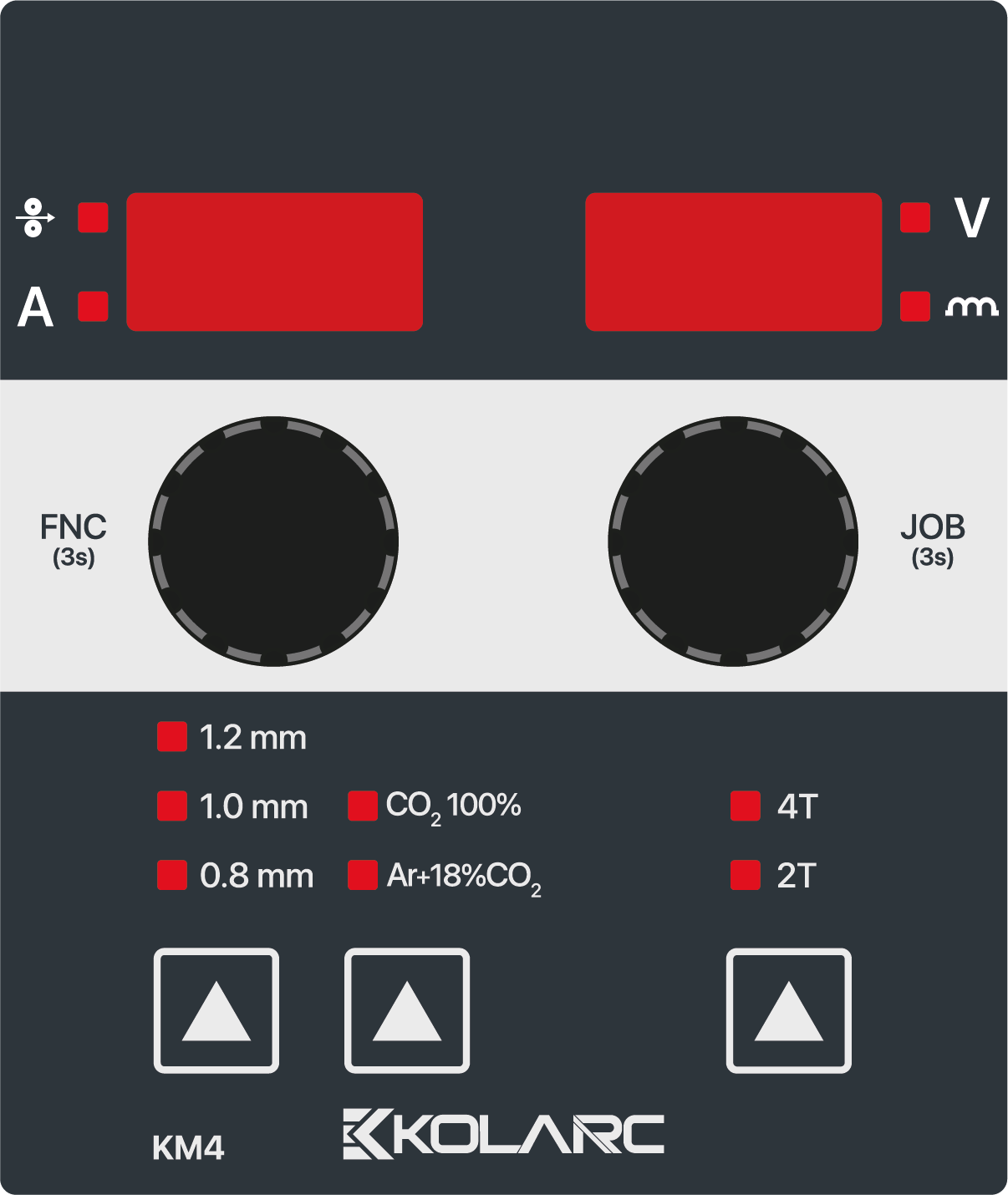

High welding speed, low heat input

Synergic keeps the voltage constant after droplet transfer by rapidly reducing the welding current vertically to a certain reference level. This increases the welding speed, resulting in low heat input and an intensified arc.

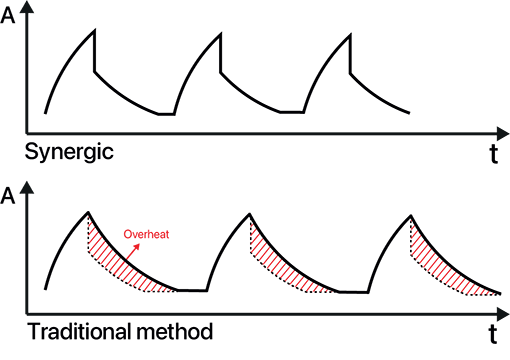

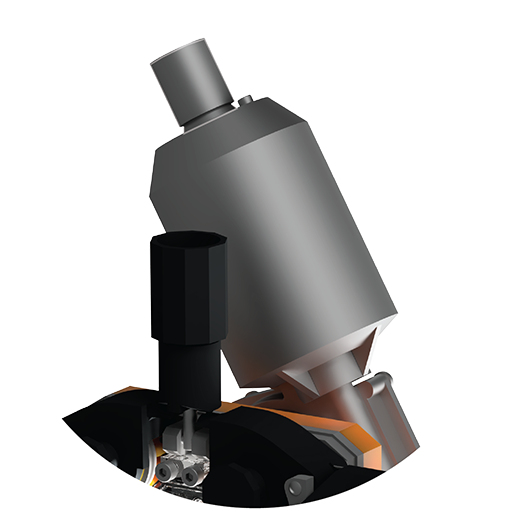

4x4 wire feeder unit

With 4 channels and 4-groove, 32 mm ball-bearing wire feed rollers, a strong grip is provided to the wire without damaging its physical form. This feature enables uninterrupted wire feeding while eliminating wire breakage issues.

256 PPR optical counter

By controlling the wire speed 50.000 times per second, it ensures that the welding wire reaches the weld pool at a constant rate. This feature minimizes the impact of conditions that negatively affect wire feeding speed on the weld, such as torch bending, contamination in the wire path, and narrowing of the contact tip diameter.

Military standard connector

It offers durability, sealing, protection against electromagnetic interference, high transmission performance and easy removal and installation.

Smart cooling

Intelligent cooling fan technology, which is only activated when needed, reduces noise, dust accumulation inside the machine and energy consumption. Increases cooling fan and fluid pump life up to 7 times.

Hose pack support

Hose supports on the wire feed unit and trolley prevent the outer sheath from being stripped off during movement. Easily removable, these hose supports ensure that power, communication, gas and water connectors are securely attached to the machine.

Reach Us

LET’S CREATE SOLUTIONS FOR YOU.

Share your opinion and inquiry with us and we’ll get back to you as soon as possible.